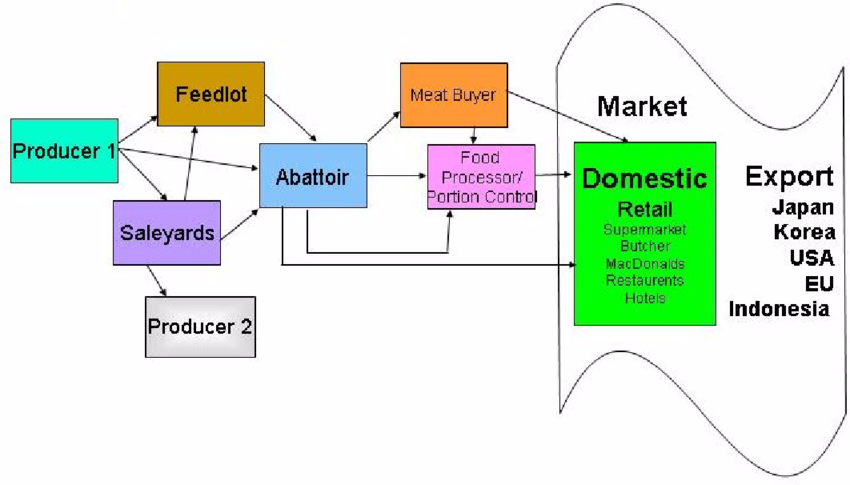

Lean Canvas (Value Proposition) Model for an Ireland based Organization for Red Meat Supply Chain

Developed Lean Canvas (Value Proposition Canvas) for Red Meat Supply Chain. Through a Value Stream map the bottlenecks are identified and then using Therblig Study, OEE Analysis, Line Balancing and Lean tools, the process is streamlined.

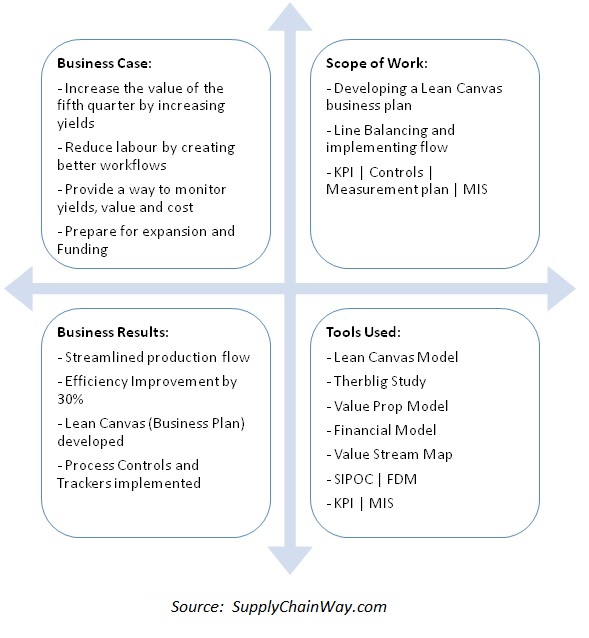

Business Case:

- Increase the value of the fifth quarter by increasing yields

- Reduce labor by creating better workflows

- Provide a way to monitor yields, value and cost

- Prepare for expansion and Funding

Scope of Work:

- Developing a Lean Canvas business plan

- Line Balancing and implementing flow

- KPI, Controls, Measurement plan, MIS

Business Results:

- Streamlined production flow

- Efficiency Improvement by 30%

- Lean Canvas (Business Plan) developed

- Process Controls and Trackers implemented

Tools Used:

- Lean Canvas Model

- Therblig Study

- Value Prop Model

- Financial Model

- Value Stream Map

- SIPOC | FDM

- KPI | MIS

About the company

The organization is based of Ireland; their mission is to provide a specialist solution for meat companies to harvest all the fifth quarter products, increase the value of the fifth quarter by increasing yields and producing top quality products from the gut room that are well presented, provide a way to monitor yields, value and cost.

Business Results

I) The project created the business plan for the organization considering the expansion and the customer value proposition. Since the project demands the business plan to be done within 2 weeks, Lean canvas model is the methodology used to document the business plan.

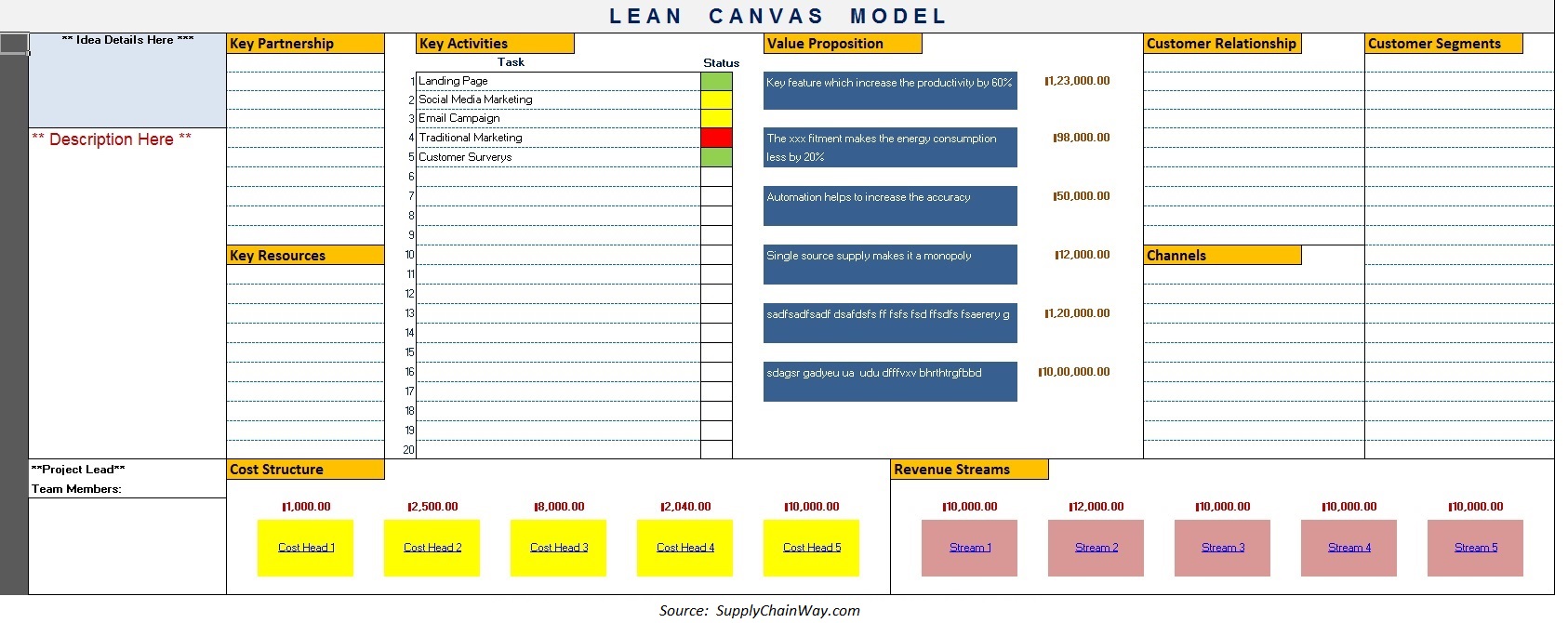

Lean Canvas model had the following sections and also the model is made as an automatic tool as shown below:

Sections of the Model:

- Market Info

- Supply and Demand

- Team Information

- Business Problem

- Solution

- Key Metrics (KPI)

- Value Proposition

- Competitive Edge

- Distribution Channels

- Supply Chain Diagram

- Cost Structure (Acquisition costs, Supply chain, Infra, People, tech etc)

- Revenue Streams (Revenue model, Monetization, Revenue, Gross Margin, Life Time Value)

II) Production Automation, Control and Reporting

Multiple Production tracking, control and reports are developed and implemented. Process controls are set in such a way the output is tracked and compare with the standards. Also, a CAPA system is implemented to ensure that the business process issues are fixed as we identify them.

In Nutshell,

- Streamlined production flow

- Efficiency Improvement by 30%

- Lean Canvas (Business Plan) developed

- Process Controls and Trackers implemented

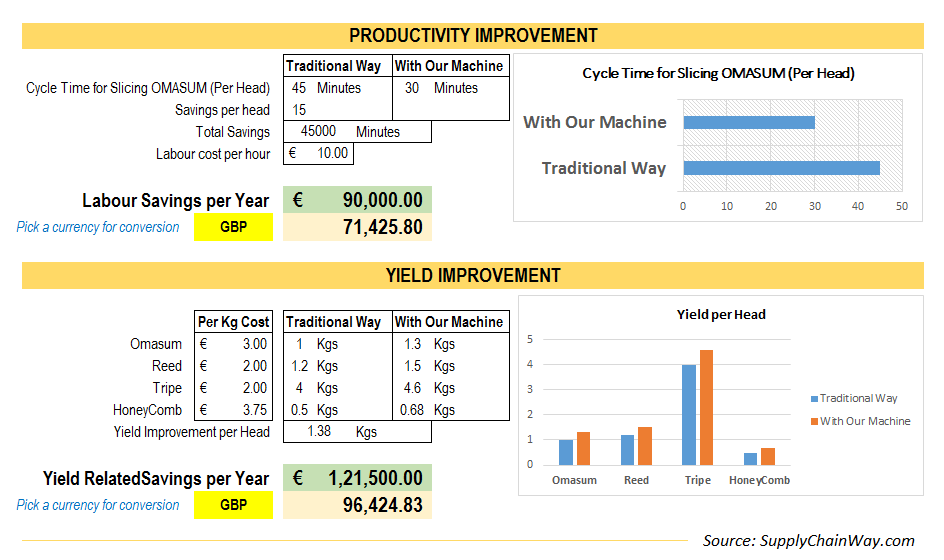

Snapshot of the Value prop which yielded more than 30% of value prop than the prevailing benchmarks of the Industry. This was achievable through strict systems and processes.

** Actual business masked or changed to ensure the key business data is preserved.