Food Delivery Supply chain Optimization

Food Delivery Supply Chain Optimization Model for an European Internet company, Dubai. This project focus on SCM modelling and Logistics Simulation to optimize food delivery supply chain at Dubai. The model captures all key supply chain process data points and dynamically builds its BI capability on an on-going basis. Thereby, it is capable of forecast and suggest action plans.

PROJECT SUMMARY

Food Delivery Supply Chain Optimization Model for the Internet company, Dubai. This project focus on SCM modelling and Logistics Simulation to optimize food delivery supply chain at Dubai.

The model captures all supply chain process data and dynamically builds it’s BI on a on-going basis. Thereby, it is capable of forecast and suggest action plans.

Food Delivery App Overview

This start-up is a food delivery app from Dubai.

Food delivery app supply chain optimization covers resource planning, logistics planning, consolidation, transit hubs, scheduling and routing. This modelling and optimization is tricky because of following constraints to the model:

- Spread of Supply

- Order Skew in a Month

- Order Skew by hours of operation

- Customer tolerance time (service level)

- Order Spread

- Knocked down cycle times

- Efficiency

- Delivery Lag

- Traffic Factor

- Human Factor

- Customer Factor

- Supply Factor

Business Results

Successfully completed the Food Delivery Supply Chain Optimization Model for the Internet company; the following are the sections of the model:

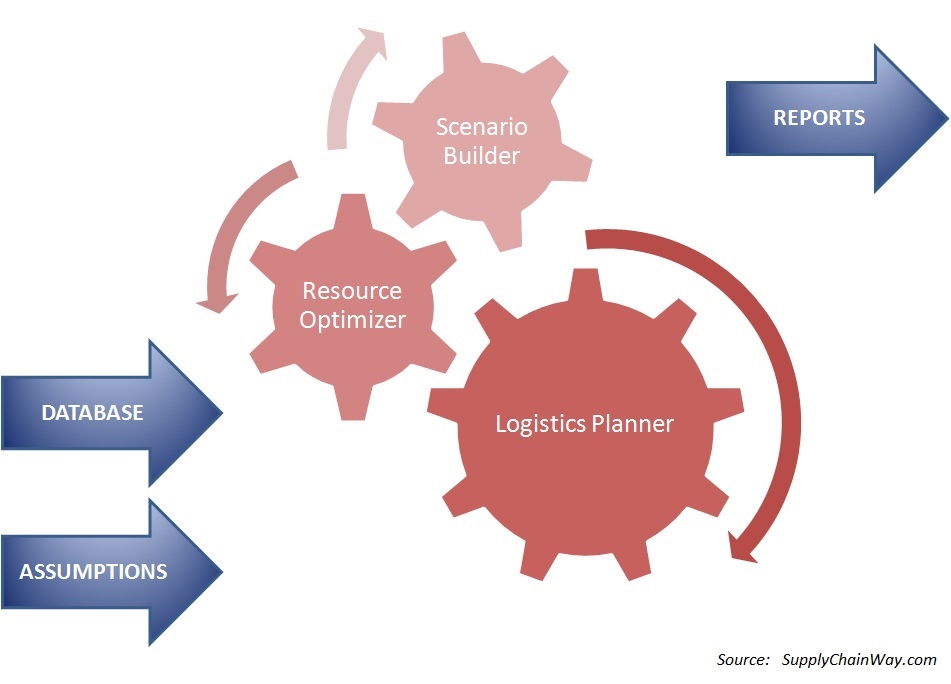

This work describes a five-stage model for Food Delivery Supply Chain Optimization:

– Stage I is ‘Building the Masters and data structuring’. The collection of basic data which would work as input masters to plan the ‘Logistics Planner’ in stage II. Note: When initiating the model i.e. pre-launch phase, the Food Delivery Supply Chain Optimization will be fed with all the Input data and then model starts validating the initial data and refine them with actual data.

– Stage II is the ‘Logistics Planner’ which uses all the key inputs, assumptions, S&OP, resource availability, cycle times, resource efficiency, etc. to do the logistics planning and daily scheduling and routing. It would also do the forecasting based on S&OP.

– Stage III is the ‘Supply Chain Optimization phase’ wherein the data is further drilled down to optimize the resources. The most complex algorithms run here to optimize the resources with all the 12 constraints discussed earlier. SCM Optimizer will do the optimization between all the counter balancing supply chain activities.

– Stage IV is for ‘Scenario Builder’ which works on creating various scenarios on Food Delivery Supply Chain Optimization model to understand the dynamics of the business. The most exciting phase where-in we give multiple scenarios and the model supports with the operational decisions and insights on financials. Most of the knowledge in this industry, standards and the key learning are added as algorithms in back end such that the model uses that deliver the key support on supply chain decisions.

– Stage V describes the type of ‘Process Controls and MIS reports and dashboards’ to be maintained to continuously monitor and improve the operations to achieve cost – service level optimization.

Summary: –

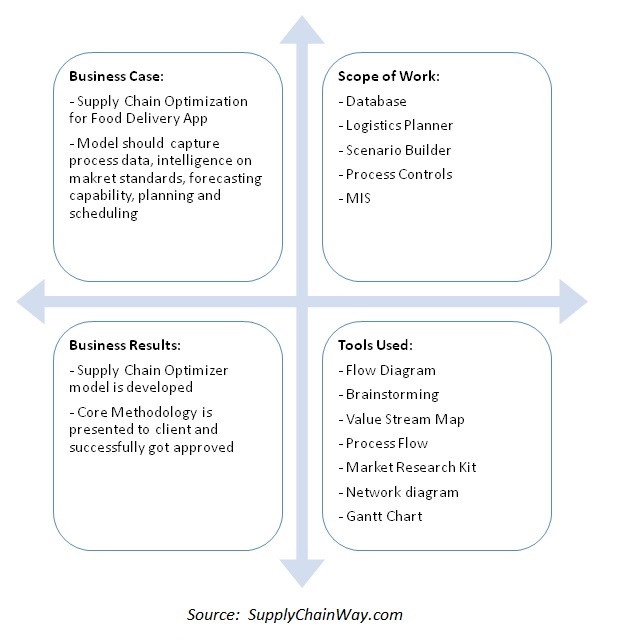

Business Case:

- Supply Chain Optimization for Food Delivery App

- Model should capture process data, intelligence on makret standards, forecasting capability, planning and scheduling

Scope of Work:

- Database

- Logistics Planner

- Scenario Builder

- Process Controls

- MIS

Business Results:

- Supply Chain Optimizer model is developed

- Core Methodology is presented to client and successfully got approved

Tools Used:

- Flow Diagram

- Brainstorming

- Value Stream Map

- Process Flow

- Market Research Kit

- Network diagram

- Gantt Chart