Secret Recipe to solve complex Supply Chain Issues

It took me more than 15+ Years before I’m able to confidently pen down the secret recipe to solve supply chain problems.

Supply Chain Problem?

Before we move forward, let’s set the definition of a supply chain problem clear. Though there are hundreds of supply chain problems, all these problems add up to two main issues.

- Customer Experience

- Supply Chain Cost

While the things like Product function, Availability, On-time, Quality etc. come under the customer experience, things like Utilization, Productivity, Optimization, Network etc. come under the supply chain cost. To be very precise, I would even say that the supply chain cost is a sub set of the customer experience. Since, if a business is not efficient on unit economics, it is highly impossible to deliver the highest levels of customer experience.

“Even on a price sensitive market like India, Not the Price but the seamless Customer Experience alone will ensure returning customers!”

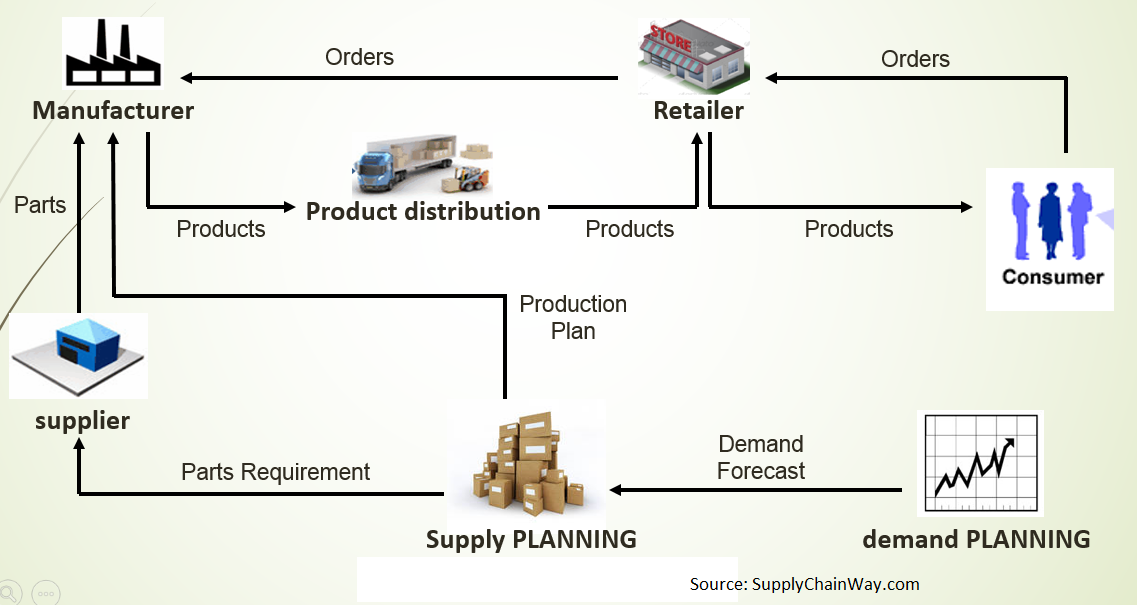

An illustration of a supply chain model has been shown below:

As I have explained, the expectation from the supply chain model is to manufacture and deliver the right product at right cost and at the right time to the customer. In the language of Kano Model, this is a basic need. And the basic needs will never be told to you by the customer.

“Right product, Right Time and Right Cost being Basic Needs (Kano Model) and never been told is the very reason why thousands of dollars are spent in understanding what exactly the customer wants.”

When any of these basic needs are not met by the business, then that becomes a burning supply chain problem which needs to be fixed to be competitive in the business.

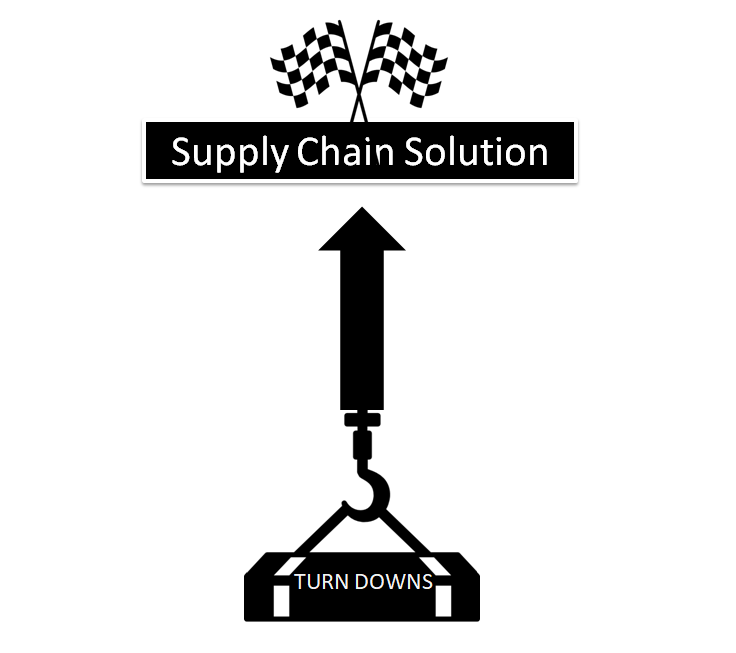

Major Turn Downs

Before using the secret recipe, you should first understand the real turn downs which will delay the progress towards the right supply chain solution.

1) Your Supply Chain Experience –

Unbelievable isn’t it? It is the hard fact that your own supply chain experience is the first major bottleneck. Past supply chain experience gives you a gut feel that your known way is the best way. Unfortunately, in supply chain solution design, never a known solution or a solution solely by experience would effectively solve the business problem.

In my supply chain problem solving career for decades, I have worked on hundreds of supply chain solutions but never a solution of a particular supply chain problem becomes the ideal fit for another supply chain problem.

“To avoid this bottleneck during Supply Chain Solution Design, you have to learn to unlearn!”

Each Supply chain problem have to treated as a new challenge and have to be tackled/fixed leveraging on the Supply Chain Basics and data rather than solely on past experience. I have seen real life situations where-in highly experienced SCM Managers fighting over two different solutions (what they believe is right); but the hard reality is both known solutions without data backup are not a fit for the organization, you have to use the data and arrive at one!

2) Relying more on Certainty –

This is a crucial point during the phase of supply chain problem solving. Most of the supply chain professionals purely rely on what they see… i.e. data collection, analyzing data using some tabular form, graphs and trends is what I mean. This doesn’t hold good at all for Supply Chain Solution design.

The one element that is so challenging and exciting in Supply Chain is the Uncertainty. Mere Assumptions (so easy) without trying to quantify the uncertainty will yield you half-baked solutions only. The real challenge is how best you estimate the in-certainty.

“In a Supply Chain Solutions design, the solution which best quantifies the uncertainty is the clear winner.”

The best tips to quantify the uncertainty are by (1) using statistical tools and models, (2) run what-if scenarios (start using Excel Solver) and (3) Simulate using Existing data

3) Boil the Ocean –

I picked up this Phrase from my SCM-VP boss in 3M India and started liking it so much thereafter (it’s so true). Indeed, Supply Chain is an Ocean; not only that, there is nothing called as the Best Solution and there is only an Optimum solution because of the complex interdependencies. Thereby, Boil the Ocean kind of problem solving will take ages and no one is going to wait for that much of time.

“So, what needs to be done? Learn to Prioritize. This sounds so simple, but a Supply Chain which doesn’t follow prioritized problem solving will never be in the Race.”

Secret Recipe to Solve Supply Chain Problems

I have clearly explained the major turn downs which will delay the supply chain solution design as well as mislead you most times. Now, the actual secret recipe in Supply Chain Solution Design and to effectively solve Supply Chain Problems is to avoid those Turn Downs.

“In a Nutshell – Seeing each Supply Chain Problem with fresh eyes, Effectively quantifying the Uncertainty, Data driven solution design rather than solely experience driven and Focused efforts on the Priorities collectively forms the SECRET RECIPE in Supply Chain problem solving arena.”