‘Delay in Supply Chain’ is too Good?!!!

Delay in Supply Chain is too good? Even I was puzzled the same way when I had my first interaction with a core supply chain management concept (Strategy) called ‘Product Postponement’. In a layman’s term, postponement can be ideally termed as ‘Delay’ – probably to be more precise, we would term that as an ‘Intentional Delay’ of a step which creates variation in final product down the value stream of Supply Chain.

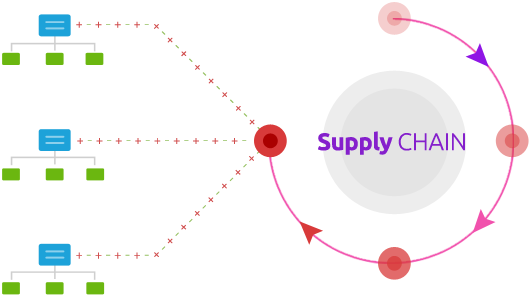

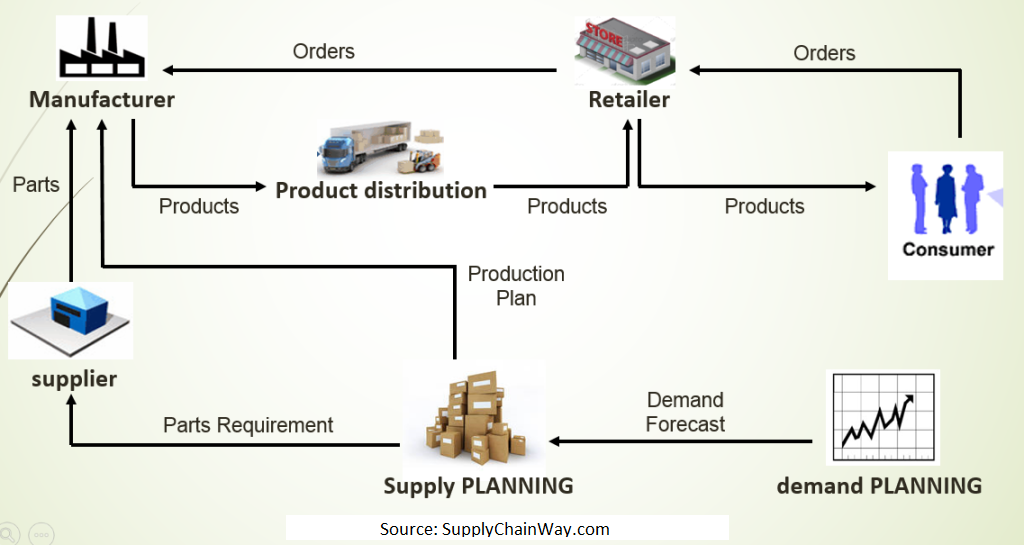

A basic supply chain is depicted in the figure below:

In this Supply chain stream of closely linked processes, as we postpone the activities that creates variation in the final product down the value stream, the value we gain is huge. Sounds Interesting?

Before we go to the real supply chain benefits from product postponement, let’s understand this concept using a common and known product – “Ice Gola”. Ice Gola comes in 15+ flavors and when we mix these flavors we get more than 200+ different flavors and all that is needed is Crushed Ice and Color flavored syrups. If we closely watch the way the Ice Gola vendor stocks and serves is – vendor has crushed ice in a big box and all the flavored syrups in separate bottles. All these are stored in a small cart or even in a bicycle. With this infra, the vendor will be able to serve a mix of 200+ SKUs in no time and with least inventory. Actually, product postponement helped the vendor to achieve this. Think of a situation the process of adding the flavored syrup is done at crushed ice stage itself and then stored in boxes. How many boxes would be needed? How to transport them? The size of shop needed? Unsold products? Now it’s clear how a simple postponement helped the Ice Gola vendor to run a lean business with maximum customer satisfaction with more variety.

Similarly, in supply chain across different industries the value the supply chain postponement strategy can bring in is so valuable. For example, Dell uses this postponement strategy to keep all the parts ready and assemble only when an order is received from the customer. All Auto OEMs uses this strategy to push the final painting down the stream as much as possible. If we take logistics, direct to customer distribution channel from a centralized warehouse is also a supply chain postponement strategy.

In Supply chain postponement, we have different types like … 1. Make to stock, 2. Assemble to order, 3. Make to order, 4. Engineer to order and 5. Innovate to order. As we move to right hand side, the flexibility is more but also there will be negative impact on the lead time to customer and effort on management.

No matter what ever the supply chain may be, the supply chain postponement would be a most powerful concept to adopt. Take the current booming E-Commerce industry, in this process steps like kitting, labeling, packing etc. are kept downstream as much as possible to have good flexibility before the last mile logistics delivery. Even these are part of supply chain postponement strategies.